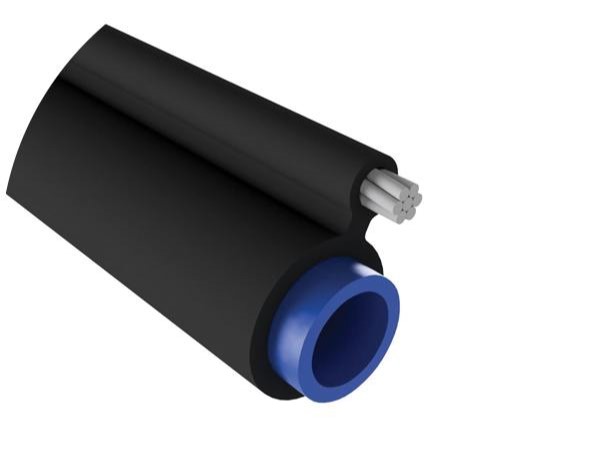

Wall-mounted Microduct

The wall-mounted microduct is an advanced and cost-effective solution for implementing the «Last Mile» segment of FTTP (Fiber To The Premises) fiber optic networks. Designed specifically for installation on building walls and in urban spaces, this product enables fast and sustainable network expansion without the need for excavation or bulky cabling.

In urban projects requiring fiber optic installations along congested routes with many obstacles, the wall-mounted microduct offers a flexible, scalable, and economical approach. With its microcable blowing capability, this system enhances network capacity, simplifies maintenance and repairs, and significantly reduces installation time and cost.

Features:

Advantages of Deploying Networks with Wall-mounted Microducts:

Compared to Drop or ADSS cables, deploying a network with wall-mounted microducts is faster, more flexible, and more stable.

Pass through obstacles without continuous cabling, using connectors along the routeAerial microduct systems offer easy scalability for future infrastructure expansion.

In case of failure, only the cable inside the duct is replaced—no need to dismantle the pathMicroducts enable low-cost and easy branching from existing paths.

Cross-street routing up to 200 meters without the need for expensive ADSS cables and accessories.

Higher physical durability compared to Drop or ADSS cables (up to 8 times)

Much higher fiber capacity (up to 144 cores in quad-pipe structures)

- Eliminates the need for splicing at distribution points, enabling relocation of low-capacity cables

- Reduced signal loss due to fewer splices and interruptions

- Easy and low-cost future scalability with new cable blowing

- Enables connection of BTS sites without fiber and provides backup paths for existing BTS units

Technical Features of Wall-mounted Microducts:

- Can withstand air pressure up to 50 bar during cable blowing operations

- UV resistance up to 20 years in outdoor environments

- Longitudinal tensile strength from 10 to 200 meters in windy and stormy conditions

- Dual-layer coating with high resistance to mechanical pressure

- Equipped with hard, deep grooves to enhance cable blowing performance

- Resistant to long-term extreme temperature fluctuations

- High flexibility against bending while maintaining pipe alignment

- Material designed with mechanical memory to retain form in harsh environments