Microduct

Abadis Dynamic Technology Underground Microducts are designed and manufactured using advanced technology and high-quality raw materials to guide and protect fiber optic cables in buried installations. Made from high-density polyethylene (HDPE), these ducts offer excellent mechanical and chemical resistance, making them highly durable against soil pressure, impacts, moisture, and corrosive substances.

With reliable performance and long service life, Abadis Dynamic Technology underground microducts are an ideal solution for FTTx deployments, telecom network expansion, smart city infrastructure, and other fiber optic applications in underground environments.

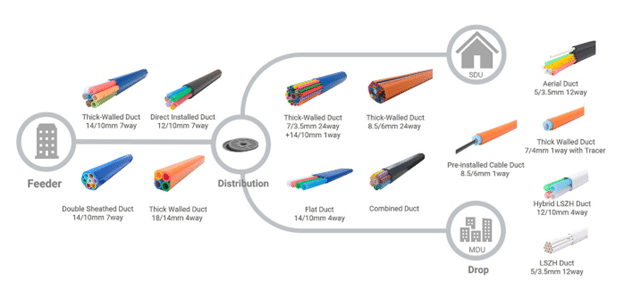

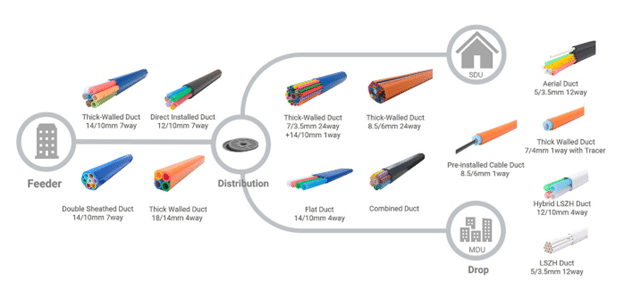

Here are many types of microduct and each of them are suitable for different applications in the field.

This figure shows the various types of microduct utilized on microduct application map.

Starting out with the feeder, the most common installation method is open trenching or HDD. For this it would be appropriate to use a thick-walled duct, or a direct buried high strength duct assembly. Because the feeder cable is likely a higher capacity cable, you will want a duct that is large enough such as a 12 by 10mm or 14 by 10mm if using thick walled duct. Choose a duct assembly with enough tubes for the cables that you plan to use, plus at least one for emergency repair. If future expansion is a possibility, it is wise to leave several spare empty ducts.

Next are the distribution lines which are located closer to the subscriber in what is referred to as the last mile. Because this is in a populated area and the pathways will clearly be along the streets and sidewalks that pass by each home, you may use micro or mini trenching, in which case a flat duct or link duct would be best. Or you may continue to use an open trenching or HDD method, in which case Thick Walled Duct or direct buried high strength is a better choice. If this is a brownfield area, there may be an existing conduit, in which case direct install microduct will be the best choice to make best use of space constraints within the conduit. In either case, choose a microduct size and configuration that suits your needs. The fiber counts will likely be lower for the last mile, so a 10 by 8mm could work. Again, make sure spare capacity is factored in for emergency repair and future expansion.

Finally, for the secondary distribution or drops, A smaller 5/3.5mm duct or 7/3.5mm duct if using Thick Walled Duct is sufficient for blowing in ABF directly to the customer. If you plan to install all drops straight to the home from the secondary concentration point, a series of individual tubes can be utilized. If you plan on using duct branch closures, pick a microduct assembly with up to 24 tubes inside, which can be broken out of the bundle at the customer’s property line. These are available in Thick Walled Duct, flat style, direct buried high strength, or even LSZH if installed indoors.

Thick walled duct

THICK WALLED DUCT is designed for direct burial by having the thicker inner tube. It has the advantage for easy and fast termination with thin outer sheath. The thickness of each inner tube allows individual tubes to be used direct buried solution. This item is suitable for any construction sites such as open cut, Micro trenching, Mini trenching and HDD. This product is usually recommended to the site which requires fast and easy sheath cutting during fiber branch off from the FCP.

Optional Features:

- Various configurations with different size between 4/2.1mm and 20/16mm

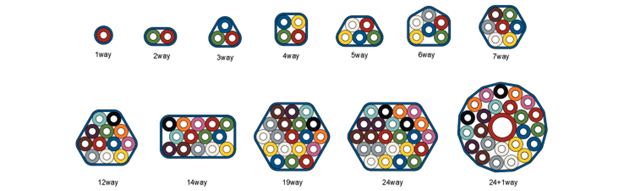

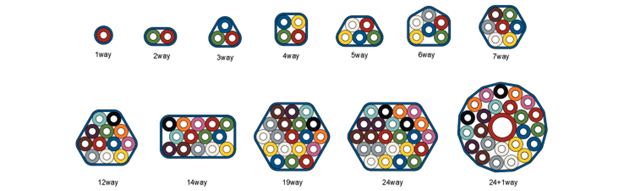

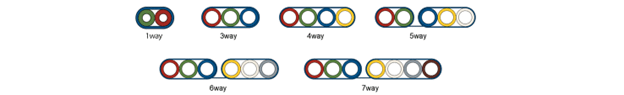

- Wide range of number of inner tube from 1 way to 24+1 way

- Ribbed & Smooth Type

- Rip cords

- Insulated Locatable copper wire

Configuration:

- 4/2.1mm 1,7,12,24way

- 7/3.5mm 1,3,4,5,6,7,12,14,19,24,24+1 way

- 10/6mm 1,3,4,5,6,7way

- 12/8mm 1,3,4,5,6,7way

- 14/10mm 1,3,4,5,6,7way

- 16/12mm 1,3,4,7way

- 18/14mm 1,3,4,6,7way

- 20/16mm 1,3,4,7way

Flat Duct

For micro-trenching with the narrow width, FLAT DUCT is the most optimized microduct. The product itself can be placed vertically to fit on micro-trenching. The size of the product is relatively small which allows better shipping and handling with the smaller reel size. Since Flat Duct has the same thickness of TWD(Thick Walled Duct), customers can enjoy the same benefits of TWD.

Optional Features:

- Various configurations with different size between 7/3.5mm and 20/16mm (Material : HDPE)

- Wide range of number of inner tube from 1 way to 24+1 way

- Ribbed & Smooth Type

- Rip cords

- Insulated Locatable copper wire

Configuration:

- 7/3.5mm 2,3,4,5,6,7 way

- 10/6mm 2,3,4,5,6,7 way

- 12/8mm 2,3,4,5,6,7 way

- 14/10mm 2,3,4,5,6,7 way

- 16/12mm 2,3,4,5,6,7 way

- 18/14mm 2,3,4,5,6,7 way

- 20/16mm 2,3,4,5,6,7 way