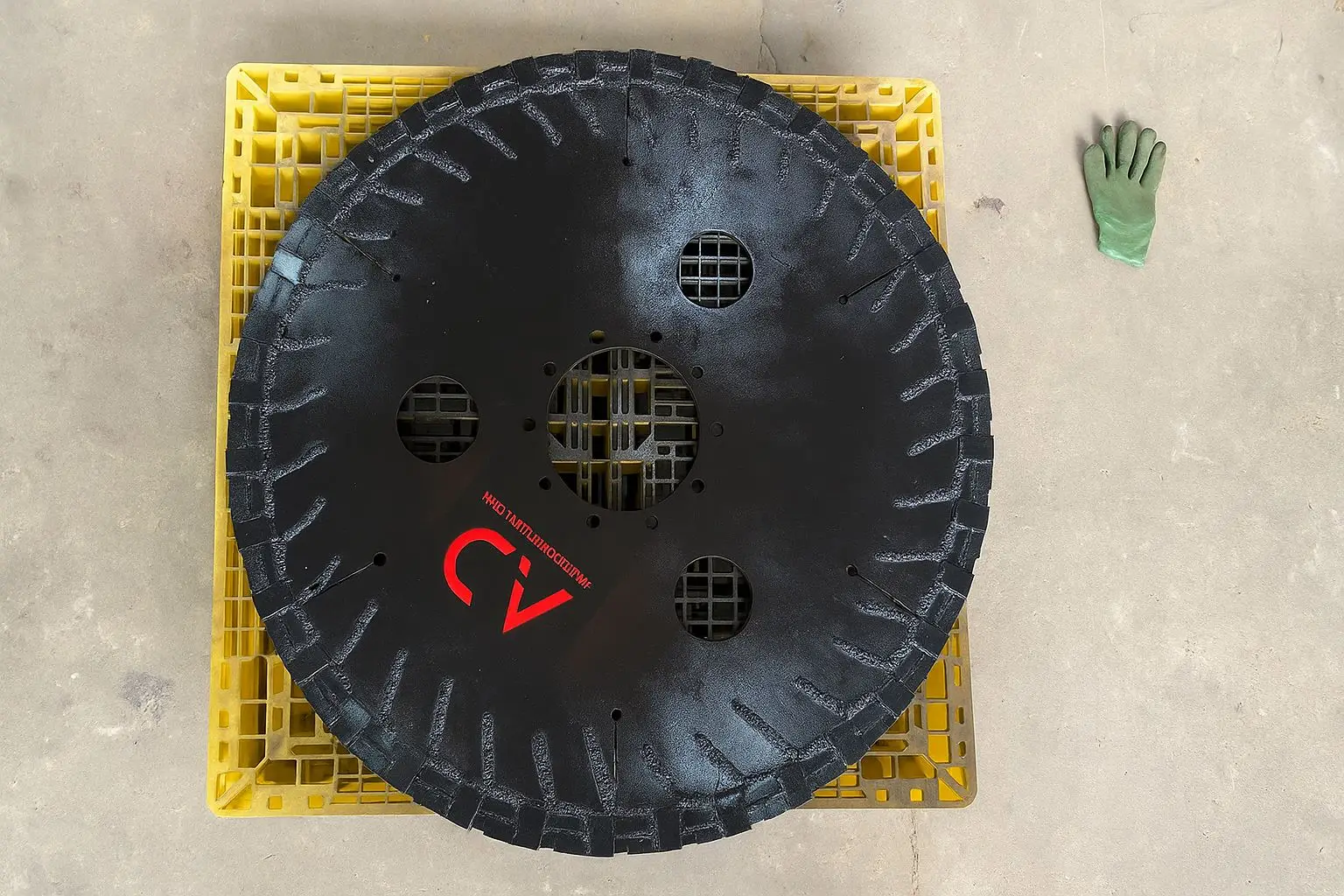

Super Micro Trencher TM-45

The tractor-mounted trencher with diamond blade is an innovative and fully localized product by Abadis Dynamic Technology, designed and manufactured for the first time in the Middle East. This machine, equipped with its exclusive diamond blade, provides an effective solution for the trenching needs of fiber optic trenching projects.

The use of a specially designed diamond blade allows for the creation of narrower trenches, which leads to reduced excavation waste, increased execution speed, and higher daily trenching output. As a result, the efficiency of execution projects is significantly improved, and additional costs are reduced.

This machine is specially developed for contractors and professionals involved in the implementation of fiber optic networks and can serve as an effective solution in telecommunication infrastructure projects.

Features:

- Trenching width between 1.5 to 3.5 cm and trench depth up to 50 cm.

- Ability to trench curved paths.

- Hydraulic jack-assisted adjustable position for the blade arm.

- Microduct carrier arm capable of lifting loads up to 1 ton using a hydraulic system.

- Cooling system with a 600 liter tank, industrial pump, and mist nozzle.

- Much higher fiber capacity (up to 144 cores in quad-pipe structures) Complete removal of debris during excavation, eliminating the need for secondary cleaning operations.enabling relocation of low-capacity cables Creation of a smooth, uniform trench bed, free from irregularities, ready for microduct placement.

- Minimal debris remaining after filling the trench, facilitating easy restoration and reducing reconstruction costs.

- Production of soft soil due to the unique performance of the diamond blade, minimizing the need for soft soil or sand.

- Reduced risk of trench wall collapse due to the cutting nature of the blade.

- Ability to excavate in hard substrates, including concrete and stone (with slower speed and increased blade wear).

- Excavation speed increased up to twice that of conventional methods (up to 6 meters per minute), improving productivity and saving time.

- Faster and cheaper restoration of the excavated path, due to the narrow trench width and reduced use of materials such as asphalt.

- Significant reduction in safety risks for pedestrians and vehicles, due to the elimination of wide trenches.

- Increased public satisfaction and reduced complaints from residents and municipalities, with the ability to increase the number of operational teams without serious disruption to traffic.

- Reduced labor force required for project execution.

- Easy connection to the tractor.