Aerial Microduct

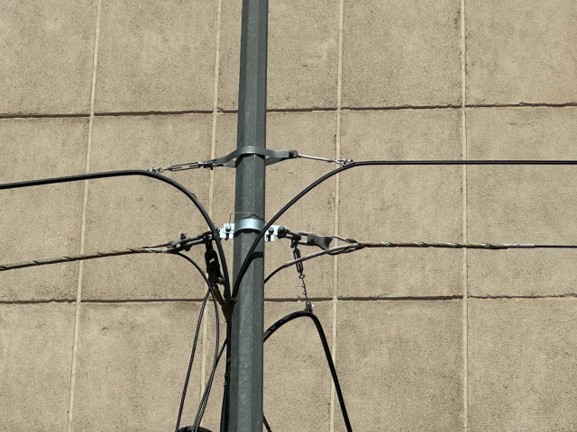

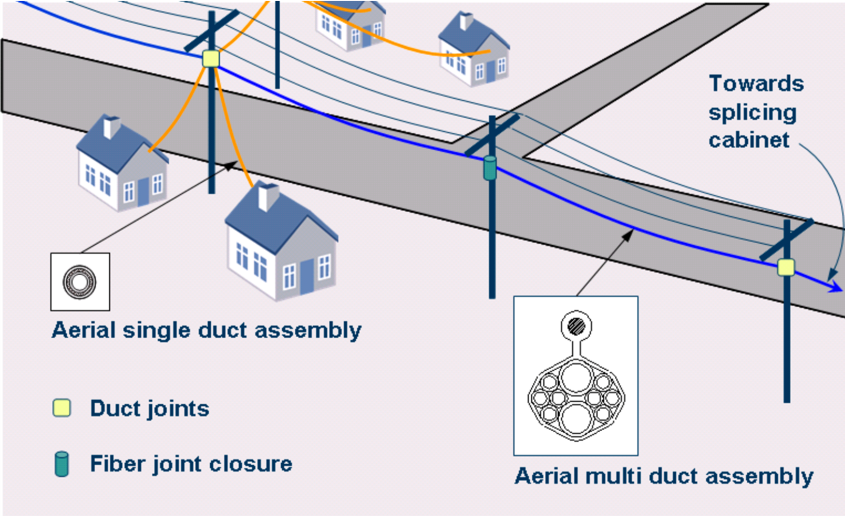

The aerial microduct system is an innovative, reliable, and cost-effective solution for deploying FTTH networks in rural, urban, and intercity areas—especially where trenching is difficult or expensive. This system enables fast, secure, and future-ready network deployment by allowing installation on existing utility or lighting poles, or on dedicated poles, with no need for excavation.

Compared to ADSS cables, this approach reduces maintenance costs by up to 30% and shortens installation time by up to 20%. Aerial microducts allow for a one-time installation, with spare paths planned in advance for future expansion—without the need for cutting and fusion splicing fiber at height.

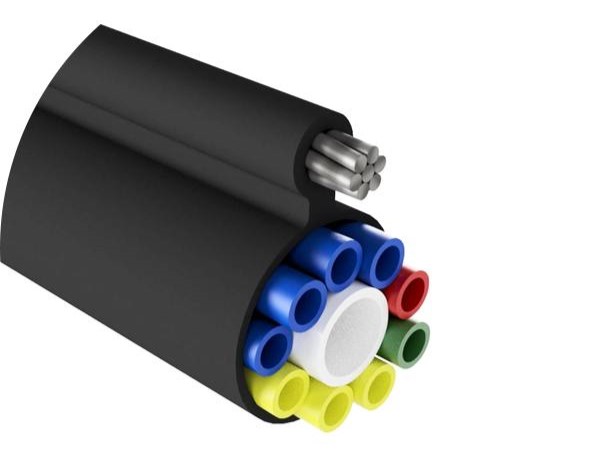

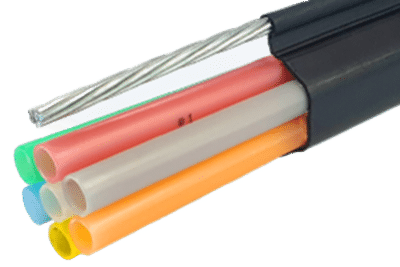

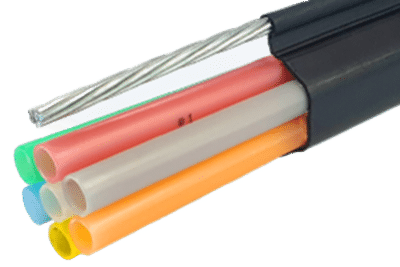

The aerial microduct is created for an environment where underground installation is not an option or for temporary construction. Designed for installation along aerial pole lines. It’s built in strength member securely attaches to the pole to create a no-lash aerial network. The metallic strength member provides superior strength for longer spans.

Features:

Advantages of Deploying Networks with Aerial Microducts:

- Aerial microducts, considering the mechanical limitations of utility poles, allow multiple fiber lines to pass through a single path—even when installing more than two cables would not be feasible.

- With microducts, multiple cables can be installed along a single route, reducing management, maintenance, and fault detection costs.

- Aerial microduct systems offer easy scalability for future infrastructure expansion.

- Instead of installing multiple cables, networks using microducts can pass several fibers through a single route, significantly lowering overall costs.

- Microducts enable low-cost and easy branching from existing paths.

- Unlike ADSS cables, microduct systems allow for multiple and closely spaced branches to be added with ease.

- Compared to standard aerial fiber optic cables, microducts offer higher durability and superior resistance to environmental damage.

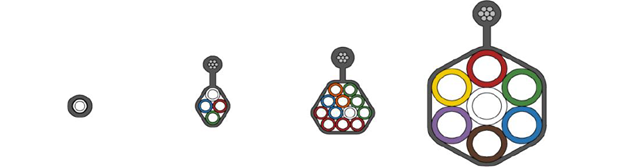

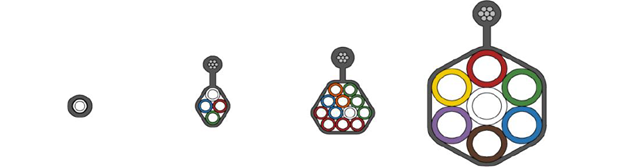

Technical Features of Aerial Microducts:

- Withstand air pressure up to 50 bar during blowing operations.

- Longitudinal tensile strength suitable for aerial spans of 10 to 200 meters.

- Dual-layer sheath with high resistance to mechanical pressure.

- Equipped with rigid and deep grooves to enhance blowing efficiency.

- Resistant to long-term extreme temperature fluctuations.

- High flexibility to withstand bending while maintaining pipe alignment.

- Constructed with memory-effect materials to retain shape in challenging environments.